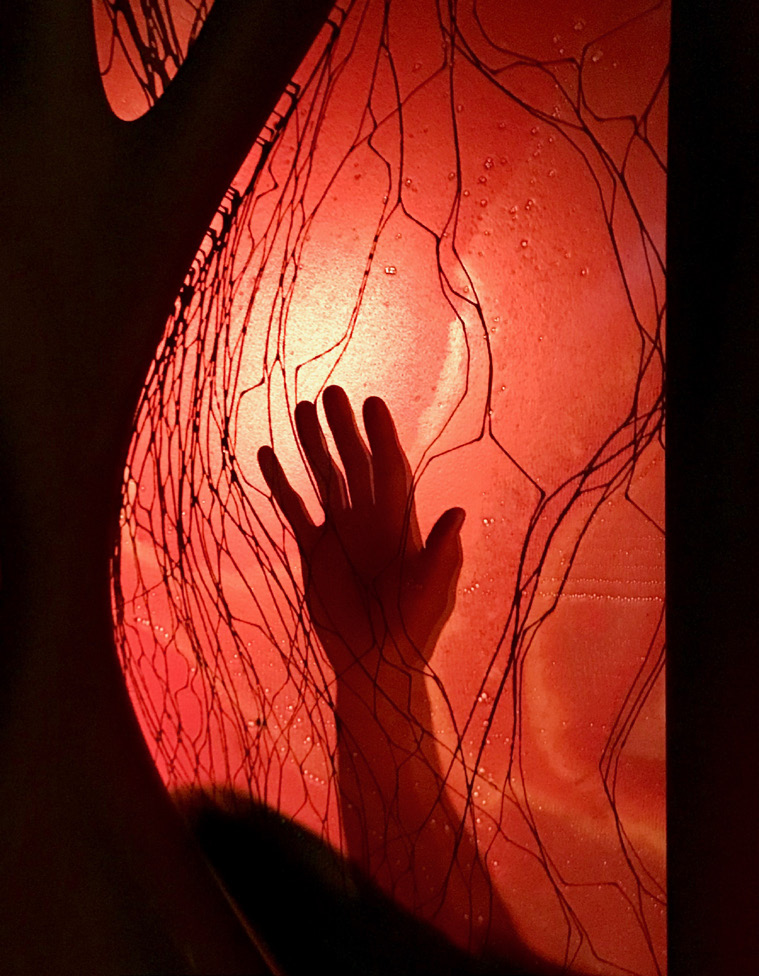

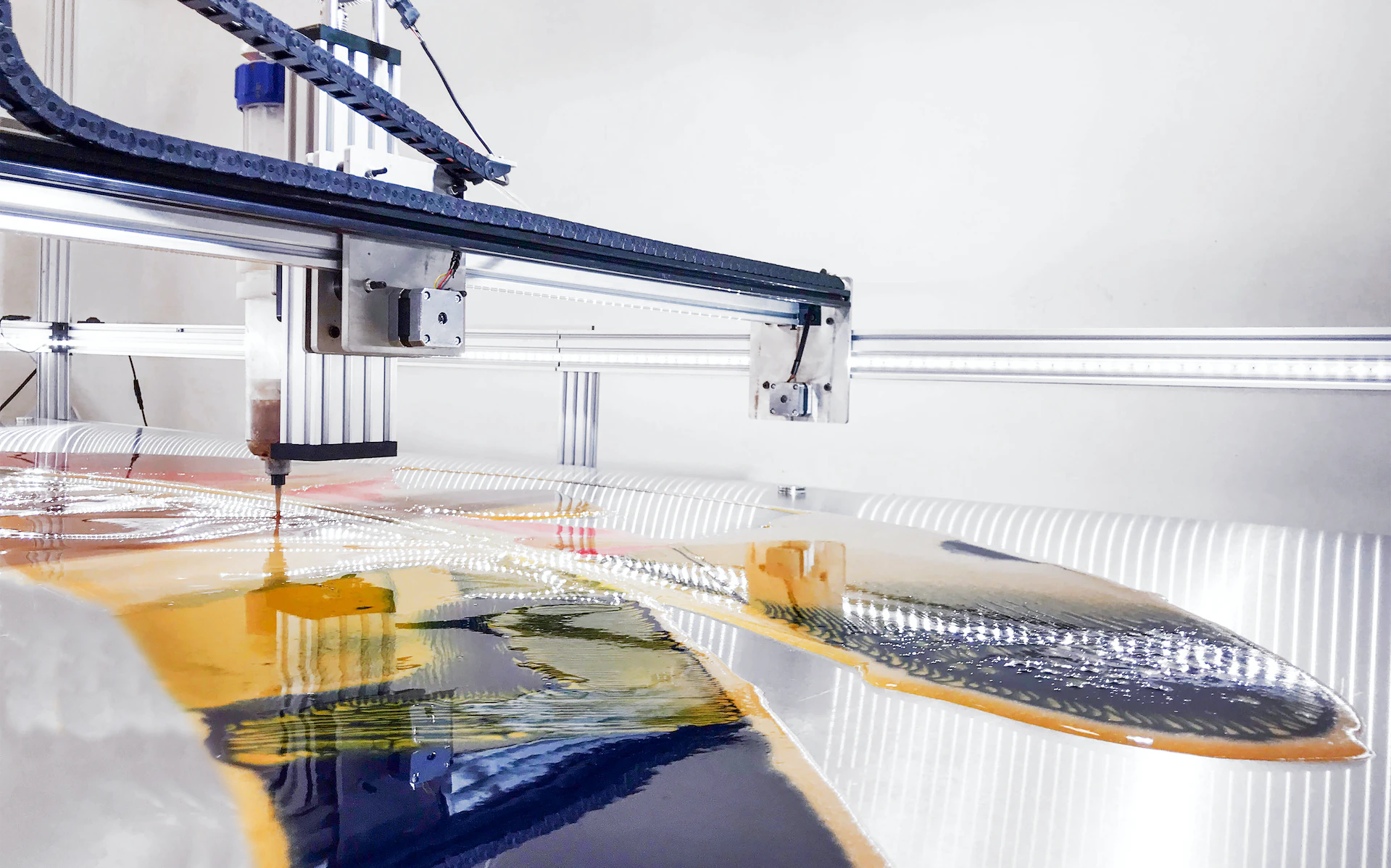

The experimental 5.2m tall structure presents advances in a water-based fabrication and novel design approaches for the 3D-printing of functionally graded bio-composites. These developments demonstrate further refinement and large-scale deployment of Water-Based Digital Fabrication in the construction of architectural-scale membrane structures. Fully biodegradable and composed of the most abundant materials of our planet —cellulose, chitosan, and water—these bio-composites represent a versatile system for the construction of dynamic membrane structures with graded mechanical and optical properties across scales.

The digital fabrication system, based on the Fabrication- Information Modeling (FIM) approach, enables the simultaneous printing and mixing of water-soluble materials through real-time feedback-driven control logics. In this way, we explore programming material behaviors through the design of diffusion-based material gradients in biocomposite hydrogels and examine the impact of local and global material cues on the full-scale assembled structure. Novel generative design methods integrate material-specific fabrication parameters and enable data-driven, hierarchical organization of the manufacturing workflow. The parametric control of the chemical composition in the 3D printing process allows for the customization of structural, environmental performative parameters of the structures across scales. In combination, these methods comprise a scalable fabrication system for the creation of adaptable, biodegradable membrane structures with minimal need for environmental control.

SF MoMA, Nature X Humanity, 2022 (San Francisco, USA)

Cooper Hewitt Smithsonian Design Museum, Triennial, 2019. (New York, USA)

Cube Design Museum, 2019 (Kerkrade, Netherlands)

Method and apparatus for the sequential additive manufacturing of continuous material transitions in composite layers. NA Lee, R Weber, JH Kennedy, J Van Zak, DR Jorge, N Oxman, US Patent App. 17/475,008 https://patents.google.com/patent/US20220176637A1/en (Pending)

Multi-Material Printing of Multi Lengthscale Bio-composite Membranes. Nic A. Lee*, Ramon E. Weber*, Joseph H. Kennedy, Josh J. Van Zak, Jorge Duro-Royo and Prof. Neri Oxman. Proceedings of the IASS Annual Symposium 2019 – Structural Membranes 2019

Sequential Multimaterial Additive Manufacturing of Functionally Graded Biopolymer Composites. Nic A. Lee, Ramon E. Weber, Joseph H. Kennedy, Josh J. Van Zak, Miana Smith, Jorge Duro-Royo, and Neri Oxman. 3D Printing and Additive Manufacturing. Oct 2020. 205-215. http://doi.org/10.1089/3dp.2020.0171

Project as part of the Mediated Matter Group at the MIT Media Lab, in collaboration with Nic Lee, Joshua Van Zak, Joseph Henry Kennedy, Jorge Duro-Royo and Neri Oxman.

more information about the project @OXMAN